When it comes to workplace safety, having a clear and comprehensive safe work method statement (SWMS) is crucial. An SWMS is a document that outlines the high-risk construction work activities to be carried out at a workplace, the hazards arising from these activities, and the measures to put in place to control the risks. It’s a practical guide that ensures everyone from management to workers understands their roles and the safety procedures they must follow.

The importance of a basic safe work method statement template cannot be overstated. It serves as a blueprint for creating a customized SWMS that addresses the specific needs of a project while adhering to regulatory requirements. A well-crafted template simplifies the process of documenting every crucial detail, from the scope of work to the risk management process.

Creating a basic safe work method statement template involves understanding the nature of the work, identifying potential hazards, and developing control measures. The goal is to minimize the risk of workplace accidents and ensure compliance with occupational health and safety regulations. This introductory guide will walk you through the essential components of an SWMS and how to tailor it to your project’s needs.

Understanding the Structure of an SWMS

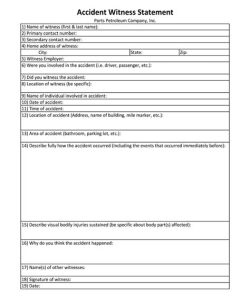

An effective SWMS is structured in a way that is easy to read and understand. The first section typically includes general information such as the project name, the date, and the parties involved. It’s essential to include contact details for those responsible for implementing and overseeing the SWMS.

The next section should detail the work activities and associated hazards. This involves a step-by-step breakdown of the tasks and a thorough hazard identification process. For each identified hazard, the SWMS should clearly outline the corresponding risk control measures.

Following this, the SWMS should address the resources required for the work, including labor, equipment, and materials. This ensures that all necessary preparations are made to carry out the work safely and efficiently.

Lastly, the SWMS should include a section for worker acknowledgment. This is where workers sign off to confirm they have read, understood, and agreed to follow the SWMS. This acknowledgment is crucial for ensuring accountability and compliance on the job site.

Developing Effective Risk Control Measures

Identifying hazards is only half the battle; developing effective control measures is key to mitigating risks. The hierarchy of control provides a systematic approach to selecting the most effective control measures. It ranges from eliminating the hazard entirely to using personal protective equipment as a last resort.

Substitution, isolation, and engineering controls are preferred over administrative controls and personal protective equipment because they tend to be more effective in reducing risk. For example, replacing a hazardous substance with a less hazardous one (substitution) or isolating the hazard with barrier systems (isolation) can significantly reduce the likelihood of an incident.

Administrative controls, such as training and procedure changes, are also important but should be used in conjunction with other controls. Personal protective equipment, while essential, is considered the least effective control measure because it does not eliminate the hazard.

When documenting control measures in the SWMS, it’s important to be specific. Vague statements like “use caution” are not sufficient. Instead, detail the exact steps and equipment required to mitigate the risk.

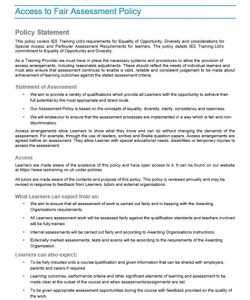

Ensuring Compliance and Continuous Improvement

Compliance with the SWMS is not a one-time event but an ongoing process. Regular reviews and updates are necessary to ensure the SWMS remains relevant and effective. Changes in work practices, legislation, or the work environment can all necessitate updates to the SWMS.

Training and communication are also critical components of compliance. Workers need to be trained on the SWMS and its updates. Clear communication ensures that everyone is aware of their responsibilities and the safety procedures they must follow.

Monitoring and auditing are essential for verifying compliance. Regular inspections and audits help identify areas where the SWMS may not be followed or where improvements can be made.

Encouraging worker feedback is another important aspect of continuous improvement. Workers are often the first to notice potential hazards or issues with existing control measures. Their input can be invaluable in enhancing the SWMS.

In conclusion, a basic safe work method statement template is a vital tool for managing safety in construction work. It helps to standardize the approach to identifying and controlling risks, ensuring a safer work environment. By following the guidelines outlined in this article, you can develop an SWMS that not only meets legal requirements but also fosters a culture of safety and continuous improvement.

Remember, the ultimate goal of an SWMS is to prevent workplace accidents and injuries. By diligently applying the principles discussed here, you can contribute to a safer and more compliant construction industry.