When it comes to asbestos removal, safety and compliance are paramount. A method statement is a critical document that outlines how a particular task or project will be carried out safely. In the case of asbestos removal, this document becomes even more crucial due to the hazardous nature of the material involved. The asbestos removal method statement template serves as a guide to ensure all safety protocols are adhered to, and that the work is performed in a manner that minimizes risk to workers and the environment.

The importance of a comprehensive method statement cannot be overstated. It not only provides a step-by-step guide to carrying out the work safely but also serves as a legal document that can be referred to in the event of an incident. As such, it must be thorough, clear, and specific to the job at hand. A well-crafted asbestos removal method statement template can be the difference between a job that is safe and one that is not.

Creating an asbestos removal method statement requires detailed knowledge of the procedures involved in asbestos handling and removal. It should cover areas such as site preparation, PPE requirements, emergency procedures, and waste disposal. Each of these sections must be tailored to the specific circumstances of the job, taking into account factors such as the type and condition of the asbestos, the location of the removal site, and the presence of other hazards.

Understanding Asbestos and Its Risks

Before delving into the method statement, it’s essential to understand what asbestos is and why it’s hazardous. Asbestos is a group of naturally occurring fibrous minerals known for their durability, fire resistance, and insulating properties. However, when asbestos fibers become airborne and are inhaled, they can cause serious health issues, including asbestosis, lung cancer, and mesothelioma.

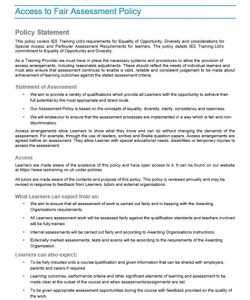

Due to these risks, asbestos use has been heavily regulated, and its removal requires strict adherence to safety guidelines. The first step in any asbestos removal project is to conduct a thorough risk assessment. This assessment will inform the method statement and ensure that all potential hazards are identified and mitigated.

Asbestos can be found in a variety of building materials, especially in structures built before the 1980s. Common products containing asbestos include insulation, floor tiles, roofing shingles, and cement pipes. Identifying the presence of asbestos is a job for professionals, as it often requires laboratory analysis of samples.

Once the presence of asbestos is confirmed, planning for its safe removal can begin. This involves selecting the appropriate removal method, which can range from encapsulation to complete removal. The chosen method will depend on factors such as the asbestos type, its condition, and its location within the building.

Preparation and Safety Measures for Asbestos Removal

Preparing for asbestos removal is a meticulous process that begins with setting up the work area. This includes installing containment barriers to prevent the spread of asbestos fibers, ensuring proper ventilation, and establishing decontamination units for workers.

Personal Protective Equipment (PPE) is another critical aspect of preparation. Workers must be equipped with respirators, protective clothing, and gloves. The type of respirator used should be suitable for the level of asbestos exposure anticipated during the removal process.

Training is also a vital component of preparation. Workers involved in asbestos removal must be trained in the proper use of PPE, decontamination procedures, and the specific method of asbestos removal being employed. This training should be documented and included in the method statement.

Another important preparation step is notifying the relevant authorities about the asbestos removal project. Depending on the jurisdiction, this may involve submitting the method statement and obtaining permits. Failure to comply with these regulations can result in significant fines and legal repercussions.

Execution and Monitoring of Asbestos Removal

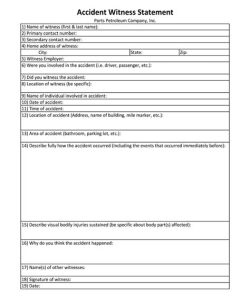

The execution of the asbestos removal process must be closely monitored to ensure compliance with the method statement. Supervisors should be on-site to oversee the work and ensure that safety protocols are being followed.

Monitoring also includes air quality testing to detect the presence of asbestos fibers. This testing is crucial to ensure that the containment measures are effective and that the work environment remains safe for the workers and the public.

Documentation is a key part of the execution phase. All activities should be recorded, including the amount of asbestos removed, the methods used, and any incidents that occur. This documentation will be an essential part of the project records and may be required for future reference.

Upon completion of the removal, a final inspection and air monitoring should be conducted to confirm that the area is free of asbestos contamination. Only after this confirmation can containment measures be dismantled, and the area be declared safe for re-entry.

In conclusion, an asbestos removal method statement template is a vital tool for ensuring the safe and compliant removal of asbestos. It provides a structured approach to planning and executing the work, with an emphasis on safety and adherence to legal requirements. By following a comprehensive method statement, workers can carry out asbestos removal projects with confidence, knowing that they are minimizing the risks to themselves and the environment.

Remember, the key to successful asbestos removal is meticulous planning, thorough training, and strict adherence to safety protocols. With these elements in place, the risks associated with asbestos can be effectively managed, ensuring a safer workplace and community.